How to Produce Dry Ice: A Complete Guide for UAE Businesses

Ever wondered how those mysterious white clouds at a concert or that perfectly preserved seafood shipment actually happen? Here’s the thing: it all starts with knowing how to produce dry ice. And honestly, if you’re in Abu Dhabi or anywhere in the UAE, understanding this process isn’t just fascinating it’s potentially profitable. Whether you’re looking to start a business or just curious about the science, I’ve got you covered. Let me walk you through everything from the basics to the nitty-gritty details that even seasoned professionals might miss. Looking for a reliable Dry Ice Supplier? You’re in the right place.

Now, before we dive deep into the mechanics, let’s get real for a second. Dry ice production isn’t rocket science, but it’s not exactly child’s play either. It requires the right equipment, proper safety measures, and a solid understanding of the process. But don’t worry I’ll break it down in plain English, none of that technical jargon that makes your eyes glaze over.

What Exactly Is Dry Ice and Why Should You Care?

Think of dry ice as the cooler cousin of regular ice literally. While regular ice is frozen water (H₂O), dry ice is frozen carbon dioxide (CO₂). The magic? It skips the liquid phase entirely. At normal atmospheric pressure, it goes straight from solid to gas at a bone-chilling -78.5°C (-109.3°F). This process, called sublimation, is what creates those dramatic fog effects you’ve seen.

But here’s where it gets interesting for business folks in the UAE. The demand for dry ice uses has skyrocketed in recent years. From preserving temperature-sensitive pharmaceuticals to creating Instagram-worthy dining experiences, dry ice has become indispensable. And in a hot climate like Abu Dhabi’s? The applications are endless.

I’ve seen businesses transform their operations just by incorporating dry ice into their logistics. Food companies extend shelf life during transport. Event planners create unforgettable atmospheres. Medical facilities ensure vaccine integrity. It’s versatile, it’s effective, and best of all it leaves zero residue.

How to Produce Dry Ice: The Science Made Simple

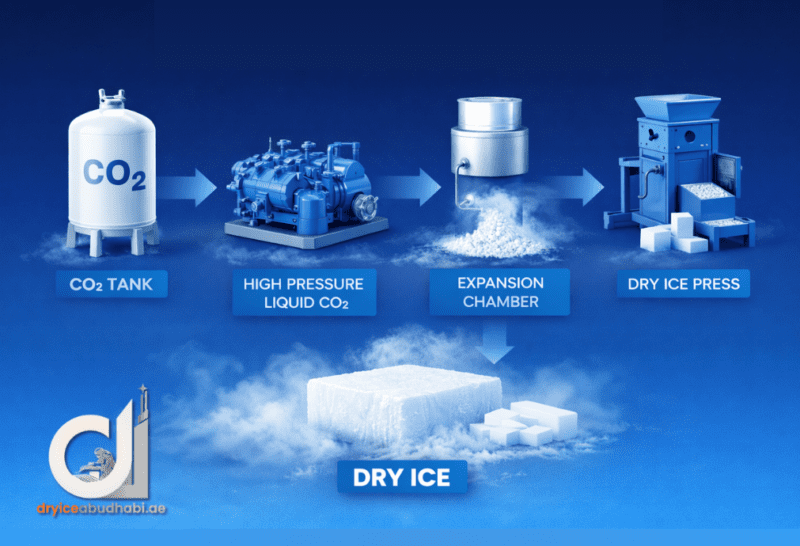

Alright, let’s get into the meat of it. How to produce dry ice starts with understanding liquid CO₂. Picture this: carbon dioxide gas is compressed and cooled until it liquefies. Then comes the fun part rapid expansion. When you release that liquid CO₂ into normal atmospheric pressure, it flash-freezes into snow-like particles. These particles are then compressed into either pellets or blocks, depending on your needs.

The process follows basic thermodynamics, but here’s what most guides won’t tell you: the quality of your end product heavily depends on the purity of your source CO₂ and the precision of your equipment settings. I’ve seen businesses cut corners on CO₂ quality and end up with inferior dry ice that sublimates too quickly or contains impurities. Not ideal when you’re trying to preserve premium goods or maintain food-grade standards.

Temperature control is critical throughout. The liquid CO₂ needs to be stored at approximately -20°C under pressure. During the expansion phase, the temperature drops dramatically. Your equipment must handle these extreme temperature swings without compromising production quality.

Understanding Liquid CO₂ Expansion in Dry Ice Production

This is where the magic truly happens. Liquid CO₂ expansion is the heart of dry ice production. When pressurized liquid CO₂ (typically stored at about 300 psi and -20°C) is released through a specialized nozzle or expansion valve, roughly 46-50% of it instantly converts to dry ice snow. The remaining 50-54% becomes CO₂ gas.

Now, here’s a pro tip from someone who’s consulted with producers across the UAE: your expansion rate matters enormously. Expand too quickly, and you’ll get fluffy, low-density snow that’s hard to pelletize. Too slow, and you’re wasting time and losing efficiency. Finding that sweet spot is the art behind the science.

Essential Equipment for Dry Ice Production

Let’s talk hardware. You can’t just MacGyver your way into dry ice production you need specialized equipment. And yes, it’s an investment, but one that pays dividends if you’re serious about entering this market.

The Dry Ice Pelletizer: Your Production Workhorse

Think of a dry ice pelletizer as a specialized pasta maker for CO₂. It takes that fluffy snow created during liquid CO₂ expansion and compresses it through cylindrical dies to create uniform pellets. These typically range from 3mm to 16mm in diameter though 3mm and 9mm are the industry standards you’ll see most often.

A quality dry ice machine will give you consistent pellet density, which directly affects sublimation rate. For businesses in Abu Dhabi doing dry ice supplies, pellets are often preferred because they’re easier to handle, dispense, and transport. Plus, they fit into those automated cleaning systems that are becoming increasingly popular in industrial settings.

Production capacity varies wildly. Small commercial pelletizers might produce 50-100 kg/hour, while industrial models can churn out 500+ kg/hour. Your choice depends on your target market and production goals.

Dry Ice Block Press: For Heavy-Duty Applications

When pellets won’t cut it say, for long-distance shipping or extended cold storage you need a dry ice block press. This beast takes that same CO₂ snow and compresses it into dense blocks, typically ranging from 10kg to 30kg each.

Blocks sublime slower than pellets, making them ideal for applications where you need sustained cooling over 24+ hours. I’ve worked with seafood exporters who swear by blocks for their international shipments. The density and uniform composition mean predictable sublimation rates crucial for logistics planning.

What Makes a Commercial Dry Ice Maker Worth the Investment?

A true commercial dry ice maker is a complete system, not just a single machine. You’re looking at:

- Liquid CO₂ storage tanks with proper insulation and pressure regulation

- Expansion chambers designed for optimal snow formation

- Pelletizing or pressing equipment with adjustable settings

- Safety systems including pressure relief valves and ventilation

- Collection and storage solutions to minimize sublimation loss

Quality systems also include automated controls that regulate flow rates, monitor pressure, and adjust production parameters in real-time. This automation isn’t just convenient it’s essential for maintaining product consistency and maximizing yield.

Different Methods to Make Dry Ice: Which One’s Right for You?

Not all dry ice production is created equal. The method you choose directly impacts your product quality, operational efficiency, and ultimately your bottom line. Let me break down the primary approaches you’ll encounter in the industry.

The batch production method works well for smaller operations or businesses with fluctuating demand. You produce dry ice in discrete batches, which gives you flexibility but requires more hands-on management. Each batch cycle typically takes 15-30 minutes from start to packaged product, depending on volume and form factor.

Continuous Production Systems for High-Volume Operations

For serious commercial operations, continuous production systems reign supreme. These setups run non-stop, feeding liquid CO₂ through expansion chambers and pelletizers in an uninterrupted flow. The efficiency gains are substantial we’re talking 20-30% higher yields compared to batch systems, plus consistent product quality that batch methods struggle to match.

Here’s what makes continuous systems compelling: minimal downtime, predictable output rates, and automated quality control. You set your parameters, monitor your dashboards, and the system handles the heavy lifting. Of course, you’re also looking at significantly higher capital investment often double or triple the cost of equivalent batch equipment.

The break-even point? Most operators find that if you’re producing more than 500kg daily, continuous systems start making financial sense. Below that threshold, batch production might serve you better unless you’ve got rock-solid demand forecasts justifying the investment.

Hybrid Approaches: The Best of Both Worlds?

Smart operators in Abu Dhabi are increasingly adopting hybrid systems that combine batch flexibility with continuous production efficiency. Picture this: a continuous pelletizer that you can pause and restart quickly, paired with batch-oriented block presses for specialty orders.

This setup lets you maintain steady pellet production for your regular customers while accommodating special block orders without completely reconfiguring your line. It’s particularly valuable in markets like the UAE where demand patterns can shift dramatically based on season, events, and industrial activity.

Quality Control in Dry Ice Production: Why It Matters More Than You Think

Look, I’ve seen operations cut corners on quality control, and it always always comes back to bite them. Whether you’re running a small dry ice supplier operation or a major production facility, quality control separates professionals from amateurs.

First up: density testing. Your dry ice density should consistently fall between 1,400-1,600 kg/m³. Too low? You’ve got premature sublimation and unhappy customers. Too high? You’re potentially damaging your compression equipment and wasting energy. Simple density checks using calibrated containers should happen multiple times per shift.

Purity Testing: Non-Negotiable for Food-Grade Applications

If you’re supplying the food industry, pharmaceutical sector, or medical facilities, purity testing isn’t optional. Your CO₂ source should provide certificates, but smart operators verify. Gas chromatography equipment might seem like overkill, but for high-value contracts, it’s insurance against costly recalls or reputation damage.

Beyond chemical purity, watch for physical contaminants. Oil from compression equipment, particulates from storage tanks, and moisture contamination all can compromise your product. Regular visual inspections combined with periodic lab analysis keep you ahead of problems.

Finding Your Niche: Dry Ice Markets in the UAE

Abu Dhabi’s dry ice market has some unique characteristics you won’t find in cooler climates. The extreme heat creates both challenges and opportunities. Transportation losses run higher expect 15-20% sublimation during delivery versus 5-10% in temperate regions. But demand? It’s robust and growing.

The aviation sector alone consumes massive quantities of airline catering. Think about it every Emirates flight departing from Abu Dhabi or Dubai needs proper cold chain management for food service. Then you’ve got the pharmaceutical cold chain, which has exploded since COVID vaccine distribution. Medical facilities need reliable, consistent dry ice in UAE supply for everything from lab samples to specialized treatments.

The Event Industry: High-Margin Opportunities

Don’t sleep on the events market. Abu Dhabi hosts hundreds of high-profile events annually concerts, exhibitions, corporate galas, weddings. Event planners pay premium prices for dry ice effects, often 2-3x standard commercial rates. The catch? They need reliability, quick delivery, and sometimes custom solutions.

I know a supplier who built an entire business division around event support. They maintain a rapid-response fleet for last-minute orders, offer on-site consultation for special effects, and charge accordingly. Their event division generates 40% of revenue despite representing only 15% of volume. That’s the power of understanding your market segments.

Industrial Dry Ice Blasting: The Sleeping Giant

Here’s a segment most new entrants overlook: industrial cleaning with dry ice blasting. Oil and gas facilities, power plants, and manufacturing operations they all need regular equipment cleaning without disassembly or chemical residues. Dry ice blasting delivers both, and the UAE’s industrial sector is massive.

These clients typically want 3mm pellets for optimal blasting performance, they order in bulk, and they value consistency over price. Lock down 2-3 industrial clients with regular maintenance schedules, and you’ve got a revenue foundation that carries you through seasonal fluctuations in other segments.

The Step-by-Step Dry Ice Production Process

Okay, theory’s great, but let’s get practical. Here’s exactly how commercial dry ice production happens from start to finish:

Step 1: Source and Store Liquid CO₂

First things first you need high-quality liquid CO₂. In the UAE, you’ll typically source this from industrial gas suppliers. For food-grade applications (which most businesses require), ensure your CO₂ meets FDA or equivalent standards. Your supplier should provide certificates of analysis.

Store the liquid CO₂ in insulated tanks at approximately -20°C under 300 psi pressure. Tank size depends on your production volume, but most small-to-medium operations work with 500kg to 2-ton tanks.

Step 2: Controlled Expansion

This is the critical phase. Liquid CO₂ flows from your storage tank through an expansion valve or nozzle. As pressure drops to atmospheric levels, the liquid flash-freezes into CO₂ snow while simultaneously releasing CO₂ gas.

The key? Control the flow rate. Too fast creates loose, fluffy snow. Too slow wastes time and CO₂. Most commercial systems aim for a flow rate that produces snow with the ideal density for subsequent compression typically around 400-600 g/liter.

Step 3: Compression into Final Form

Now your fluffy snow becomes usable dry ice. For pellets, the snow feeds into your pelletizer where hydraulic pressure forces it through cylindrical dies. The compression increases density dramatically from that 400-600 g/liter snow to 1,400-1,600 g/liter solid pellets.

For blocks, a hydraulic press applies thousands of pounds of pressure to compress snow into solid rectangular forms. The pressing time typically ranges from 30 seconds to 2 minutes, depending on block size and desired density.

Here’s an insider secret: the temperature of your compression equipment matters more than most realize. Keep dies and press plates cold (but not too cold around -40°C is optimal) to minimize sublimation during compression while maintaining good flow characteristics.

Step 4: Immediate Storage and Packaging

Time is your enemy here. Dry ice begins sublimating immediately you’re losing roughly 5-10% of your product per day even under good storage conditions. That’s why professional operations have insulated storage bunkers or containers ready to receive product as it’s made.

Package in insulated containers with minimal air space. Some operations use specialized coolers; others opt for thick-walled polystyrene boxes. Whatever your choice, the goal is the same: minimize temperature differential and air circulation.

Critical Safety Considerations You Cannot Ignore

Look, I’m not trying to scare you, but dry ice production isn’t something to approach casually. CO₂ is heavier than air, and in enclosed spaces, it can displace oxygen. I’ve heard horror stories of warehouse workers passing out because the ventilation wasn’t adequate. Don’t be that story.

Is Special Safety Equipment Required for Dry Ice Production?

Absolutely, yes. At minimum, you need insulated gloves rated for cryogenic temperatures, safety goggles (CO₂ snow can cause eye damage), and proper ventilation systems that exchange air at least 6-8 times per hour in production areas.

But let’s go deeper. Consider installing:

- CO₂ monitoring systems with audible alarms (trigger at 0.5% concentration)

- Pressure relief systems on all tanks and vessels

- Emergency eyewash stations within 10 seconds of any production area

- Proper signage indicating hazardous areas and required PPE

- Training programs for all personnel (initial and recurring)

Smart Handling and Storage Protocols

Never, and I mean never, store dry ice in airtight containers. The sublimating CO₂ gas needs somewhere to go, or you’re creating a pressure bomb. Use vented containers designed specifically for dry ice storage.

For transport, especially in Abu Dhabi’s heat, triple-check your insulation. I recommend starting with at least 50mm of expanded polystyrene or equivalent insulation. For longer trips, consider active refrigeration to minimize sublimation loss.

Personnel should never handle dry ice with bare hands frostbite can occur in seconds. Even brief contact can cause serious cold burns. Use insulated tongs or scoops for small quantities, and proper gloves for larger handling tasks.

Advanced Dry Ice Production Techniques for Maximum Efficiency

Once you’ve mastered the basics, there’s a whole world of optimization that separates good producers from great ones. These advanced techniques can boost your yield by 5-10% and significantly reduce operating costs.

Pre-cooling your compression equipment makes a massive difference. Most operators miss this. By maintaining your pelletizer dies at -40°C rather than ambient temperature, you reduce the thermal shock when hot CO₂ snow hits the dies. Result? Less immediate sublimation, better pellet formation, higher yield. It costs maybe AED 500 monthly in additional refrigeration but saves thousands in improved efficiency.

Pressure Optimization: The Secret Sauce

Here’s something most equipment manuals won’t tell you: the optimal expansion pressure varies with ambient temperature and humidity. In Abu Dhabi’s summer, when ambient hits 45°C, you’ll get better results running slightly higher storage pressure around 320-330 psi instead of the standard 300 psi.

Why? The higher storage pressure compensates for the thermal gradient between your cold CO₂ and the scorching environment. You get more consistent snow formation and denser pellets. Winter months? Drop back to 290-300 psi for optimal efficiency. This seasonal adjustment alone can improve your yield by 3-5%.

CO₂ Recovery Systems: Reducing Waste

Remember that 50% of your liquid CO₂ becomes gas during expansion? Smart operators are installing recovery systems to capture and recompress that gas. Yes, it requires additional investment figure AED 200,000-400,000 for a system but if you’re producing 1,000+ kg daily, the ROI hits within 18-24 months.

These systems aren’t for everyone. Below 500kg daily production, the economics don’t work. But for larger operations, especially those focused on being a major dry ice Abu Dhabi supplier, recovery systems transform your cost structure and environmental footprint simultaneously.

How to Start a Dry Ice Production Business in the UAE

Now we’re talking business. Starting a dry ice production operation in Abu Dhabi or anywhere in the UAE isn’t just about buying equipment and flipping a switch. There’s real strategy involved.

What Is the Cost of Dry Ice Production?

Let’s talk numbers, because that’s what matters. A basic dry ice pelletizer starts around AED 150,000-300,000 for small commercial units. Industrial systems? You’re looking at AED 500,000-2,000,000+ depending on capacity and automation level. Then add storage tanks, safety equipment, facility modifications, and working capital.

But here’s the flip side dry ice production has relatively low operating costs once you’re set up. Your main expense is liquid CO₂, which typically runs AED 0.80-1.50 per kg in the UAE. With proper efficiency, you can produce dry ice at roughly 1.2-1.5x the cost of your raw CO₂. Sell at market rates (typically AED 3-8 per kg depending on form and quantity), and the margins become attractive.

Market Opportunities in Abu Dhabi and UAE

The UAE market is growing faster than most realize. Key sectors include:

- Food and Beverage: Restaurants, catering, food transport companies

- Pharmaceuticals: Temperature-sensitive drug transport, especially vaccines

- Events and Entertainment: Concerts, weddings, corporate events

- Aviation: Airline catering, maintaining the cold chain for air cargo

- Industrial Cleaning: Dry ice blasting for equipment maintenance

- Medical Facilities: Laboratory sample preservation, medical transport

Building relationships with anchor customers before you launch is crucial. I recommend securing at least 2-3 committed buyers who’ll take regular quantities. This steadies your cash flow and helps you plan production schedules efficiently.

Navigating Regulatory Requirements in Abu Dhabi

Let’s talk about the paperwork nobody enjoys but everyone needs. Operating a dry ice production facility in Abu Dhabi requires several permits and licenses. You’ll need an industrial trade license from the Department of Economic Development, environmental permits for CO₂ handling, and potentially food safety certifications if you’re targeting that market.

Don’t try to navigate this alone. I’ve seen entrepreneurs waste months because they missed a single requirement. Hire a local business consultant who knows the system. The AED 10,000-15,000 you’ll spend upfront saves you easily 3-6 months of delays and frustration. Time is money, especially when you’re paying rent on a facility and equipment financing.

Also consider joining relevant trade associations. The UAE has several industrial and manufacturing associations that provide networking, advocacy, and sometimes preferential access to contracts. Being part of these networks signals credibility to potential clients.

Strategic Location: Where Should You Set Up Shop?

Location matters enormously for a dry ice supplier in UAE operation. You need industrial zoning (residential areas won’t approve CO₂ handling), proximity to major transport routes, and ideally, closeness to your primary customer base.

Industrial zones in Mussafah, ICAD, or Khalifa Industrial Zone Abu Dhabi (KIZAD) offer suitable facilities. Rent runs AED 150-400 per square meter annually depending on location and facilities. Factor in at least 500-800 square meters for a medium-scale operation production area, storage, packaging, office space, and safety zones.

Ceiling height matters too. Your CO₂ tanks and pelletizer need adequate vertical clearance, plus you want good air circulation for safety. Minimum 6 meters ceiling height; 8 meters is better. And make absolutely certain your lease allows for the weight of filled CO₂ tanks those aren’t light.

Technical Specifications and Production Yields

Let’s get into the specifics that actually impact your bottom line. Understanding yields, pellet sizes, and production parameters can make the difference between a profitable operation and one that struggles.

What Is the Yield from Liquid CO₂?

Here’s the reality: from every kilogram of liquid CO₂, you’ll get approximately 0.46-0.50 kg of dry ice under good production conditions. That means roughly 50% loss but it’s not waste, it’s just physics. The other 50% becomes CO₂ gas during the expansion phase.

Optimize this yield by ensuring proper equipment temperature, optimal flow rates, and minimizing the time between production and storage. I’ve seen operations improve from 45% to 49% yield just by fine-tuning these parameters. Over thousands of kilograms, those percentage points add up to real money.

What Are Common Dry Ice Pellet Sizes?

Industry standard pellets come in three main sizes: 3mm (rice grain), 9mm (pencil eraser), and 16mm (large marble). Each has its ideal applications. The 3mm pellets sublimate quickly, making them perfect for dry ice blasting where you want rapid cooling and evaporation. The 9mm pellets offer a balance they’re the workhorse of the industry, used in everything from shipping to laboratory applications. The 16mm pellets sublimate slowly, ideal for extended cooling periods.

Most pelletizers can produce different sizes by changing die sets. However, switching between sizes requires downtime for die changes and equipment recalibration. Plan your production runs to minimize these switches batch similar orders together.

Dry Ice Pellet Size Comparison

| Pellet Size | Sublimation Rate | Best Applications | Typical Price Range |

| 3mm (Rice Grain) | Fast (2-3 hrs) | Blasting, rapid cooling | AED 6-8/kg |

| 9mm (Standard) | Medium (5-8 hrs) | Shipping, events, general use | AED 5-7/kg |

| 16mm (Large) | Slow (12-24 hrs) | Extended storage, long transport | AED 4-6/kg |

Can I Make Dry Ice at Home?

Technically? Yes. Practically? I’d advise against it for anything beyond small experiments. The internet is full of DIY methods using CO₂ fire extinguishers or compressed gas cylinders, but these approaches are inefficient, potentially dangerous, and definitely not scalable.

For small-scale needs in Abu Dhabi, you’re better off finding a reliable supplier. Companies like DryiceAbudhabi can provide consistent quality at competitive prices without the safety risks and equipment investment. Plus, they ensure food-grade quality if that’s what you need.

That said, if you’re determined to experiment, use only CO₂ cylinders designed for this purpose, work in well-ventilated areas, and never attempt to contain the dry ice in sealed containers during or after production. The pressure buildup is no joke.

What Maintenance Do Dry Ice Machines Need?

Like any industrial equipment, dry ice machines require regular maintenance to operate efficiently and safely. Here’s what you’re looking at:

- Daily: Visual inspections of pressure gauges, safety systems, and production output quality

- Weekly: Clean expansion chambers and collection systems to remove CO₂ buildup

- Monthly: Inspect seals, gaskets, and pressure relief valves for wear

- Quarterly: Calibrate pressure sensors and flow meters for accuracy

- Annually: Complete system overhaul including hydraulic systems, electrical components, and safety devices

Budget for maintenance figure roughly 5-8% of your equipment cost annually. This includes both scheduled maintenance and inevitable repairs. In Abu Dhabi’s climate, some components may require more frequent attention due to temperature extremes.

Troubleshooting Common Dry Ice Production Problems

Every producer faces issues. The difference between success and failure? Knowing how to diagnose and fix problems quickly. Let me share the most common headaches and their solutions.

Low pellet density is problem number one. You’re getting fluffy, weak pellets that sublime too fast. Nine times out of ten, this traces to either insufficient compression pressure or CO₂ snow that’s too warm when it hits the pelletizer. Check your hydraulic pressure first, which should read 3,000-4,500 psi depending on pellet size. If pressure’s good, verify your expansion chamber temperature. Snow should exit at roughly -78°C. Warmer than -75°C? You’ve found your culprit.

When Yields Drop: Quick Diagnostic Steps

Suddenly getting less dry ice from the same amount of liquid CO₂? Start with the simple stuff. Check for leaks in your expansion chamber even small leaks significantly impact yield. Listen for hissing sounds, look for frost buildup in unexpected places. A simple soap solution test on connection points often reveals the problem.

If leaks aren’t the issue, examine your expansion valve. Over time, the orifice can erode or partially clog, changing flow characteristics. This alters the pressure drop rate and affects snow formation. Manufacturers recommend valve inspection every 3-6 months for high-volume operations. For those searching for a reliable dry ice near me option, established suppliers maintain equipment meticulously to ensure consistent quality.

Dealing with Safety System Alarms

CO₂ monitor alarms going off? Don’t just reset them, that’s how accidents happen. First, evacuate personnel from the immediate area. Second, verify that ventilation systems are operating. Third, use a portable CO₂ meter to check actual concentration levels. Only after confirming safe conditions should you investigate the root cause.

Common causes include ventilation system failures, unexpected pressure relief valve discharge, or equipment leaks. Each requires different corrective action. Documenting every alarm event pattern often reveals underlying issues before they become serious problems.

Environmental Impact and Sustainability in Dry Ice Production

Let’s address the elephant in the room: CO₂ emissions. Yes, dry ice production releases CO₂ about 50% of your input becomes atmospheric gas. But here’s the nuance most people miss: the CO₂ used for dry ice production is typically captured from industrial processes that would release it anyway.

Your CO₂ supplier probably sources from ammonia plants, ethanol fermentation, or natural gas processing all operations where CO₂ is a byproduct. By capturing and utilizing this CO₂ for dry ice, you’re actually participating in a form of carbon recycling. It’s not carbon-negative, but it’s significantly better than sourcing from dedicated CO₂ wells.

Forward-thinking producers are taking this further. Some are installing solar panels to offset electricity consumption. Others are implementing heat recovery systems to minimize energy waste. As a dry ice supply near me provider, demonstrating environmental responsibility increasingly influences contract awards, especially with multinational corporations that have sustainability mandates.

Can I Produce Food-Grade Dry Ice?

Absolutely, and for most commercial applications in the UAE, food-grade is what you should be targeting. The difference isn’t in the production process it’s in the source CO₂ and facility cleanliness.

Food-grade CO₂ must meet specific purity standards (typically 99.9%+ purity) and come from sources approved for food contact. Your supplier should provide documentation proving the CO₂ meets FDA 21 CFR 184.1240 or equivalent international standards.

Your facility must maintain sanitary conditions clean equipment, pest control, and proper hygiene protocols. Consider getting HACCP certification if you’re targeting food industry clients. It’s an investment, but it opens doors to higher-value contracts.

Keep detailed records of every batch: source CO₂ certificates, production dates, and test results. Traceability isn’t just good practice; it’s increasingly a requirement for food industry suppliers.

Final Thoughts: Making Dry Ice Production Work for You

Look, producing dry ice isn’t magic it’s applied physics with commercial potential. Whether you’re considering starting your own production facility or just want to understand the process better, you now have the knowledge to make informed decisions.

For many businesses in Abu Dhabi and across the UAE, partnering with established suppliers makes more sense than DIY production. The capital investment, safety requirements, and technical expertise needed aren’t trivial. But if you’re serious about entering this market, the opportunities are real.

Remember: quality matters. Whether you’re producing or purchasing, insist on food-grade CO₂, proper safety protocols, and reliable equipment. Your reputation depends on delivering consistent, safe products to your customers.

Need dry ice in the UAE? Whether you’re after pellets for dry ice blasting, blocks for shipping, or custom solutions for specialized applications, DryiceAbudhabi has the expertise and capacity to deliver.

Got questions about dry ice production or applications? Drop them in the comments below. I love geeking out about this stuff, and I’m always happy to share what I’ve learned from years in the industry. Until next time, stay cool literally.

Frequently Asked Questions About Dry Ice Production

What is the process to produce dry ice?

Pressurized liquid CO₂ expands through a valve, flash-freezing into snow, then gets compressed into pellets or blocks.

What equipment is needed to make dry ice?

Essential equipment includes liquid CO₂ tanks, expansion chambers, pelletizers or block presses, and safety systems.

Can I make dry ice at home safely?

Home production is risky and inefficient without proper equipment; professional suppliers offer safer alternatives.

What is the yield from liquid CO₂ to dry ice?

Expect approximately a 46-50% conversion rate, with the remainder becoming gas during expansion.

Is special safety equipment required for dry ice production?

Yes, mandatory equipment includes cryogenic gloves, safety goggles, CO₂ monitors, and adequate ventilation systems.

What are the common dry ice pellet sizes available?

Standard sizes are 3mm, 9mm, and 16mm, each suited for different sublimation rates and applications.

How do I start a dry ice production business in Abu Dhabi?

Begin with market research, secure equipment and CO₂ sources, obtain permits, and build customer relationships.

What maintenance do dry ice machines need regularly?

Daily inspections, weekly cleaning, monthly seal checks, quarterly calibrations, and annual overhauls are essential.

Can I produce food-grade dry ice commercially?

Yes, using food-grade CO₂ (99.9%+ purity) and maintaining sanitary facility conditions with proper certifications.

What is the typical cost of dry ice production?

Production costs range from AED 0.96-2.25 per kg, with equipment investment from AED 150,000-2,000,000+.